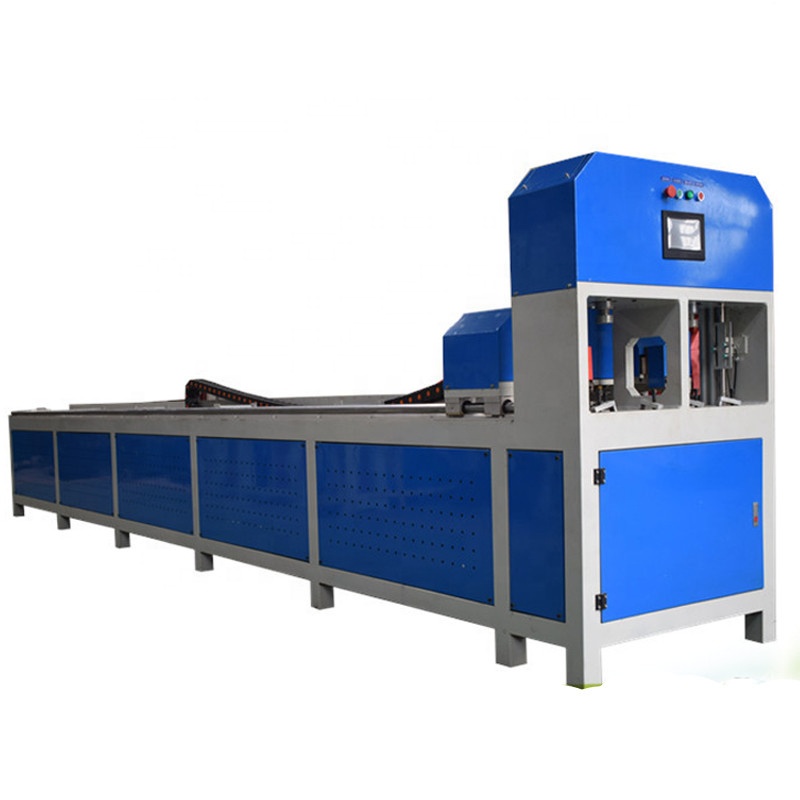

Besco cnc channel steel pipe punching machine

Besco cnc channel steel pipe punching machine,Lubrication oil:Sinopec or Exxon mobil,After-sales Service Provided:Free spare parts, Field maintenance and repair service,Applicable Industries:Building Material Shops, Machinery Repair Shops, Manufacturing Plant, $10,000.00,1 – 9 Sets

$8,000.00>=10 Sets

- Type:Automatic

- Automation:Automatic

- Color:Customized

- Cutting thickness:3-12mm

- Certification:CE ISO

- Condition:

- New

- Material / Metal Processed:

- PVC, Plastic, Brass / Copper, Stainless Steel, Carbon steel, Aluminium alloy, ALLOY, Aluminum

- Video outgoing-inspection:

- Provided

- Machinery Test Report:

- Provided

- Marketing Type:

- New Product 2020

- Warranty of core components:

- 1 Year

- Core Components:

- PLC, Bearing, Gearbox, Motor, Pump

- Automation:

- Automatic

- Place of Origin:

- Shandong, China

- Brand Name:

- Redhorse CNC

- Voltage:

- 380V

- Rated Power:

- 7.5

- Weight (KG):

- 3000

- Year:

- 2020

- Key Selling Points:

- High Productivity

- Applicable Industries:

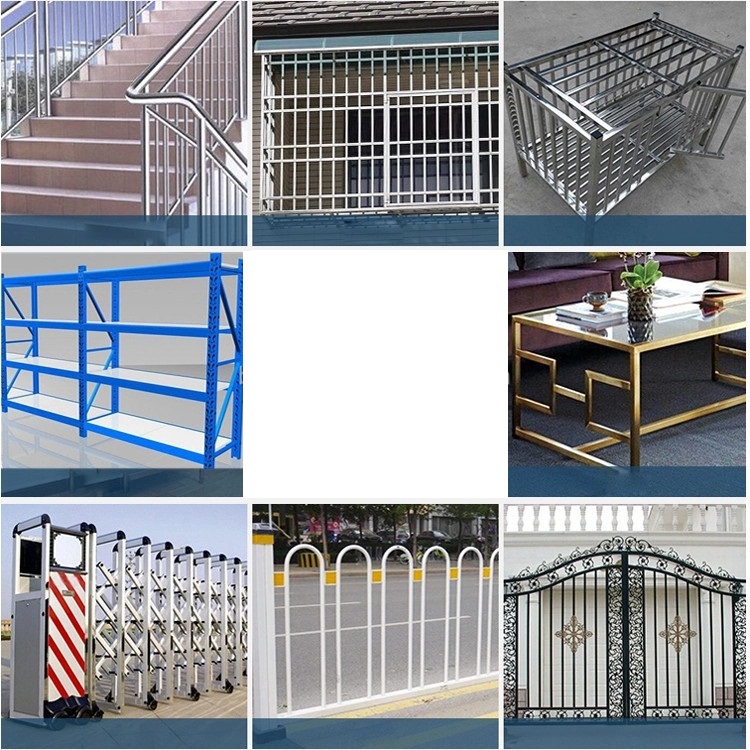

- Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Construction works , Energy & Mining, Advertising Company

- Warranty:

- 1 Year

- Showroom Location:

- None

- Type:

- Automatic

- Application:

- Industrial Metal Cutting

- Cutting mode:

- Plasma Cutting+ Flame Cutting

- Cutting material:

- Metal .alloy Metal .aluminum

- Profile Steel:

- square tube, round tube, angle iron, shelf, rectangular tube

- Color:

- Customized

- Control system:

- CNC Controller

- Memory Function:

- Can be stored and memorized

- Lubrication oil:

- Sinopec or Exxon mobil

- Cutting thickness:

- 3-12mm

- After-sales Service Provided:

- Free spare parts, Field maintenance and repair service

- After Warranty Service:

- Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

- None

- Certification:

- CE ISO

- Supply Ability

- 1000 Set/Sets per Year

- Packaging Details

- Port

| Quantity(Sets) | 1 - 1 | 2 - 5 | >5 |

| Est. Time(days) | 35 | 30 | To be negotiated |

Hydraulic Round Square Pipe double line processing Punching Press Automatic CNC

Tube Hole Pipe Punching Machine

Fully automatic CNC pipe punching machine imported Servo motor automatic feeding,accurate pitch,man-machine interface,The operation is simple,is the ideal equipment for pinching zinc steel guardrail,anti-theft network,shelf industry.

Features

Punching holes are smooth and no burrs and no deformation. Half single hole punching,double hole punching,Isometric hole punching,none- Isometric hole punching,rotary punching,Hole or Completely hole are available, The hole shape can be customized as per the request.

1.Touch Screen settings, CNC control system, precise servo motor positioning, module storage memory function, equipped with hydraulic and Servo System.

- Mould replacement: change the die easily without adjusting the dies to reduce the mould damage rate and pipe fittings rejection rate due to the dies setting error. Skillful workers can change the mould within 10 minutes.

- Step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration.

4.When the oil cylinder is moving downward, the machine is designed with hydraulic difference driving loops rated at high or low RPM .it is also featured with high speed downward moving, low speed processing and hi-speed position resume .it is available to increase the formation stability of work pieces during puncturing. In addition to increasing the activation speed, it can effectively reduce HP load to save electrical energy.

5.The electrical control system is designed with the human machine interface, range adjustment use digital scale, setting low speed position, floor level position, and operation precise and easy.

Technical parameter

| NO. | Item | Data |

| 1 | Size | Single line, Double line |

| 2 | Processing catagory set : | Single punch, not equidistant punching, equidistant punching rotary 360 degree ( can be customized ) |

| 3 | Diameter and thickness of punching processing : | Φ 50 × t 3 --- Φ 40 × t 12mm |

| 4 | Processing of pipe diameter ( can be customized ) : | square tube : 20×20 ---120×120mm |

| rectangular tube : 15×30 --- 60×120mm | ||

| angle iron : 30×30 --- 120×120mm | ||

| channel iron : 25×50 --- 120×120mm | ||

| 5 | Punching hole distance : | 0.1mm - 11900mm |

| 6 | Punching speed : | 0.8-1.5 secound/ per hole, max 180mm stroke. |

| 7 | Maximum punching distance : | 12000mm ( can be customized ) |

| 8 | Standard length of processing : | 12000mm ( can be customized ) |

| 9 | Transmiss parts : | flock and pinion drive, ball screw drive |

| 10 | Ram pressure : | 5T --- 60T |

| 11 | Punching hole method | Oil pressure |

| 12 | Power | 380V 50HZ |

| Size | According to model |

| Weight | According to model |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Pre-Sales Service

After-Sales Service

Answer: 30% down payment and the balance should be paid before shipment.

What will be the soonest delivery time?

Answer: usuall in stock, if not, the latest delivery time is 30 days.

Contact Us For A Quick Quote

Full CNC channel steel pipe punching machine

Support

Design Support

Email Support

Towable air compressor Solutions

Local Team Support on CNC channel steel pipe punching machine

CNC channel steel pipe punching machine

Manufacturers in China

CNC channel steel pipe punching machine structure of a unique design, a compact, stylish appearance, high efficiency, small energy consumption, low noise characteristics and long life, is a smart environment-friendly products. Widely applied in metallurgy, machinery, chemicals, and mining, and electric power industries of the ideal gas source equipment.

If you are looking for a manufacturer of CNC channel steel pipe punching machine in China, you are in the right place. Shandong Zollant machinery manufacturing Co., Ltd. is one of the most professional manufacturers and suppliers of CNC channel steel pipe punching machine .